|

Flow Research

has been covering vortex flowmeters since our first study in 2001. Our

current report, The World Market for Vortex Flowmeters, 7th Edition,

shows that this useful and affordable meter is still strong and continuing to

experience steady market growth.

Vortex

flowmeters, introduced to the market in 1969, are versatile, reliable and

accurate in measuring liquids, gases, and steam at a competitive price -- and

with equal ease. They are widely used for steam flow measurement and can handle

the high temperatures of both saturated and superheated steam.

Many vortex

meters today offer accuracy better than one percent, depending on the fluid and

application. They also have very favorable costs of acquisition,

commissioning and ownership.

With more

suppliers entering the market and a growing demand for gas flow measurement, we

believe vortex flowmeters are uniquely positioned for strong growth.

Since vortex

flowmeters were first introduced to the market, the number of worldwide

suppliers has grown to more than 50 and many changes have taken place in the

market. Today there are a wide variety of choices for customers to make when

specifying or purchasing vortex flowmeters. Technical innovations include

anti-vibration software and electronics, multivariable flowmeters, reduced bore

meters, plastic vortex flowmeters, and much more.

This

study examines:

-

Market

growth factors

-

Effects

of the API's adoption of a custody transfer standard on vortex sales

-

Growth

in the use of multivariable flowmeters

-

Line

sizes for vortex flowmeter applications

-

Use

of vortex meters in steam applications

-

Growing

trend towards dual sensor vortex meters

-

Importance

of reducer vortex meters

-

New

product and technology developments

-

Growth

strategies for vortex flowmeter suppliers

What’s new

Despite what

has been slow growth in the vortex flowmeter market, there are signs that this

flowmeter is breaking out of its slump. One sign is the major product

enhancements that have occurred in the past five years.

In addition,

the American Petroleum Institute’s approval of its API 14.12 standard for

using vortex flowmeters in single phase gas and steam custody transfer

applications has boosted market growth as suppliers develop products that

conform to the standard.

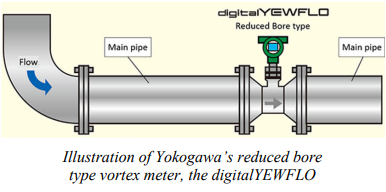

Reduced bore meters

Due to their

design, vortex flowmeters have traditionally had trouble measuring low flowrates.

Suppliers have now introduced smaller bore flowmeters that provide a stronger

signal at the point of measurement and allow the meter to more effectively and

accurately measure low flows. Our study found that both single-line size

and double-line size reduced bore vortex flowmeters have become increasingly

popular in the last few years.

Advantages of multivariable vortex flowmeters

Sierra

Instruments (now part of TASI Group) introduced the first multivariable vortex

flowmeter in 1997. Sierra had a marketing agreement with Jim Storer, who

invented the meter. This flowmeter included an RTD temperature sensor and a

pressure transducer. By using information from these sensors, together with

detection of vortices generated, the flowmeter can output volumetric flow,

temperature, pressure, fluid density, and mass flow. Multivariable flowmeters

measure more than one process variable, and typically use this information to

compute mass flow. This makes the flowmeter measurement more accurate in

fluctuating temperature and pressure conditions.

In

the past 10 years, a number of suppliers have also introduced multivariable

vortex flowmeters that use sensors to determine a variety of factors: volumetric

flow, temperature, pressure, fluid density, and mass flow. While somewhat

more expensive than their single-variable, volumetric counterparts,

multivariable vortex flowmeters provide significantly more information. They are

particularly attractive for steam and gas flow measurement and are contributing

to vortex flowmeter market size growth.

Other

suppliers that have introduced multivariable vortex flowmeters include include

ABB, Yokogawa, KROHNE, and Endress+Hauser.

Redundancy is increasingly important

In response

to user demands for increased reliability and certainty, manufacturers have

introduced two redundant configurations: 1) a single shedder bar with dual

sensors and 2) dual vortex meters calibrated and installed in tandem directly in

the flowstream. Although the traditional installation with a single shedder

bar and sensor still dominates the market, our study determined that users see

the value of measurement redundancy.

Vibration

Issues solved

One perennial problem with vortex flowmeters has been susceptibility to

vibration error. Vibrations in the line can cause a vortex flowmeter to falsely

generate a vortex signal, or to incorrectly read an existing vortex. Suppliers

have responded to issues surrounding vibration by implementing software and

electronics, including digital signal processing, that have reduced the

susceptibility of vortex meters to interference from vibration.

How they work

Vortex

flowmeters operate on a principle called the von Karman effect. This principle

concerns the behavior of fluids when an obstacle is placed in the path of flow.

Under the right conditions, the presence of the obstacle generates a series of

alternative vortices called the von Karman street. This phenomenon occurs in

liquid, gas, and steam, and has been observed in many diverse contexts including

cloud layers passing an island and whitewater rapids.

In vortex

flowmeters, the obstacle takes the form of an object with a broad, flat front

called a bluff body that is mounted at right angles to the flowstream.

Flow velocity is proportional to the frequency of the vortices and flowrate is

calculated by multiplying the area of the pipe times the velocity of the flow.

In order to

compute the flowrate, vortex flowmeters count the number of vortices generated

by the bluff body using a variety of techniques. The majority of vortex

flowmeters use a piezoelectric sensor to detect vortices, however some use a

capacitive or ultrasonic sensor.

Flow Research

has been covering vortex flowmeters since our first study on them in 2001. Our

latest report, The World Market for Vortex Flowmeters, 6th Edition,

shows that this useful and affordable meter is still strong and continuing to

experience steady market growth.

Vortex

flowmeters, introduced to the market 56 years ago, are versatile, dependable and

accurate in measuring liquids, gases, and steam at a competitive price -- and

with equal ease. They are widely used for steam flow measurement and can manage

the high temperatures of both saturated and superheated steam. Vortex

flowmeters, introduced to the market 56 years ago, are versatile, dependable and

accurate in measuring liquids, gases, and steam at a competitive price -- and

with equal ease. They are widely used for steam flow measurement and can manage

the high temperatures of both saturated and superheated steam.

Many vortex

meters today offer accuracy better than one percent, depending on the fluid and

application. They also have very favorable costs of acquisition,

commissioning, and ownership.

With more

suppliers entering the market and a growing demand for gas flow measurement, we

believe vortex flowmeters are uniquely positioned for strong growth.

Since vortex

flowmeters were first introduced to the market in 1969, the number of worldwide

suppliers has grown to at least 35 and many changes have taken place in the

market. Today there is a wide diversity of choices for customers to make when

specifying or purchasing vortex flowmeters. Technical innovations include

anti-vibration software and electronics, multivariable flowmeters, reduced bore

meters, plastic vortex flowmeters, and much more.

Advantages of multivariable vortex flowmeters

Vortek

Instuments introduced the first multivariable vortex

flowmeter in 1997. This flowmeter included an RTD temperature sensor and a

pressure transducer. By using information from these sensors, together with

detection of vortices generated, the flowmeter can output volumetric flow,

temperature, pressure, fluid density, and mass flow. Multivariable flowmeters

measure more than one process variable, and typically use this information to

compute mass flow. This makes the flowmeter measurement more accurate in

fluctuating temperature and pressure conditions.

In the past

10 years, a number of suppliers have also introduced multivariable vortex

flowmeters that use sensors to determine a variety of factors: volumetric flow,

temperature, pressure, fluid density, and mass flow. While more expensive than

their single-variable, volumetric counterparts, multivariable vortex flowmeters

provide significantly more information. They are particularly attractive for

steam and gas flow measurement and are contributing to vortex flowmeter market

size growth.

Other

suppliers that have introduced multivariable vortex flowmeters include ABB.

Yokogawa, KROHNE, and Endress+Hauser.

Vibration

Issues solved

One perennial problem with vortex flowmeters has been susceptibility to

vibration error. Vibrations in the line can cause a vortex flowmeter to falsely

generate a vortex signal, or to incorrectly read an existing vortex. Suppliers

have responded to issues surrounding vibration by implementing software and

electronics, including digital signal processing, that have reduced the

susceptibility of vortex meters to interference from vibration.

Redundancy is increasingly important

In response

to user demands for increased reliability and certainty, manufacturers have

introduced two redundant configurations: 1) a single shedder bar with dual

sensors and 2) dual vortex meters calibrated and installed in tandem directly in

the flowstream. Although the traditional installation with a single shedder

bar and sensor still dominates the market, our study determined that users see

the value of measurement redundancy.

Previous Vortex Flowmeter Studies

The World Market for Vortex Flowmeters, 6th Edition

Previous Study -

January 2019

The World Market for Vortex Flowmeters, 5th Edition

Previous Study -

December 2014

The World Market for Vortex Flowmeters, 4th Edition

Previous Study - July 2010

The World Market for Vortex

Flowmeters, 3rd Edition

Provides historical perspective

The World Market for Vortex Flowmeters, 2nd Edition

Provides historical perspective

The World Market for Vortex Flowmeters, 1st Edition

Provides historical perspective

|